3d printing is hype compared to cnc parts The choice between CNC machining and 3D printing depends on several factors, including the specific requirements of your project, the material you’re using, and your budget. Here’s a . Black Durable U-Clamps Metal Pipe Clamps Double Hole Double Hole Pipe Strap DIY U-Bracket (Pack of 6) (1/2 INCH) Application: They are ideal for pipe straps. These U-clamps are strong enough to hold pipes or rods securely in place.The U-shaped, two-hole design allows for easy installation on wood, drywall, exterior walls, floors, and other panels.

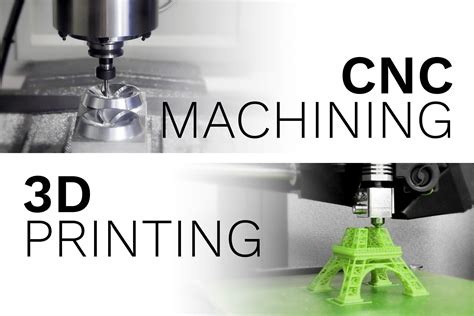

0 · 3d printing vs cnc

1 · 3d printing and cnc machining

Advanced Training on Sheet Metal Using NX-10 – The Marketplace for CAD/CAM/CAE Videos Downloadable Tutorials & Online Training. NX-10 has state-of-the-art tools for designing sheet metal components. This course will assist you to familiarize with these tools, terminology, and workflow.

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. See moreThe choice between CNC machining and 3D printing depends on several factors, including the specific requirements of your project, the material you’re using, and your budget. Here’s a . CNC offers superior surface finish and strength, while 3D printing enables the creation of lightweight, hollow structures. In terms of accessibility, 3D printing is more user-friendly and requires less technical expertise. CNC . 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making .

The benefits of 3D printing over CNC Machining include creating parts with more complex geometries, rapid prototyping, and reduced waste. Also, 3D printing allows for better . Pros and cons: CNC is faster, more accurate, and can work with harder materials, but 3D printing is cheaper, easier, and can create more complex parts with less waste. Industry applications: Both CNC and 3D printing are .

The decision between CNC machining and 3D printing ultimately depends on your project requirements, timeline, and budget. Here’s a quick breakdown to guide you: For High .Depending on your part requirements, budget, and timeline, CNC machining or 3D printing is the best choice. Here are some factors to consider: choose CNC machining for medium to high quantities of parts with simpler geometries.3D printing and CNC machining are among the most widely used rapid prototyping (RP) technologies today. Both methods enable quick production of prototypes, are suitable for . Choosing between CNC machining and 3D printing for your prototyping needs depends on the specific requirements of your project. 3D printing offers rapid, cost-effective .

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between.The choice between CNC machining and 3D printing depends on several factors, including the specific requirements of your project, the material you’re using, and your budget. Here’s a closer look at when each process might be the better choice: CNC offers superior surface finish and strength, while 3D printing enables the creation of lightweight, hollow structures. In terms of accessibility, 3D printing is more user-friendly and requires less technical expertise. CNC machining is typically faster for larger quantities, but 3D printing can be quicker for one-off parts or small runs. 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making complex net shapes. It .

The benefits of 3D printing over CNC Machining include creating parts with more complex geometries, rapid prototyping, and reduced waste. Also, 3D printing allows for better customization without retooling and offers the operator some level of design freedom and a chance to experiment and be more innovative with the design.

3d printing vs cnc

3d printing and cnc machining

Pros and cons: CNC is faster, more accurate, and can work with harder materials, but 3D printing is cheaper, easier, and can create more complex parts with less waste. Industry applications: Both CNC and 3D printing are used for prototyping and production in various industries, such as aerospace, military, and robotics. The decision between CNC machining and 3D printing ultimately depends on your project requirements, timeline, and budget. Here’s a quick breakdown to guide you: For High Precision and Strength: If you need parts that will handle heavy use, high temperatures, or stress, CNC machining is often the better choice.

Depending on your part requirements, budget, and timeline, CNC machining or 3D printing is the best choice. Here are some factors to consider: choose CNC machining for medium to high quantities of parts with simpler geometries.

3D printing and CNC machining are among the most widely used rapid prototyping (RP) technologies today. Both methods enable quick production of prototypes, are suitable for creating metal and plastic components, and deliver highly accurate results. Choosing between CNC machining and 3D printing for your prototyping needs depends on the specific requirements of your project. 3D printing offers rapid, cost-effective solutions for complex and iterative designs, while CNC machining provides high precision, material versatility, and superior surface quality for functional prototypes.Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between.

The choice between CNC machining and 3D printing depends on several factors, including the specific requirements of your project, the material you’re using, and your budget. Here’s a closer look at when each process might be the better choice: CNC offers superior surface finish and strength, while 3D printing enables the creation of lightweight, hollow structures. In terms of accessibility, 3D printing is more user-friendly and requires less technical expertise. CNC machining is typically faster for larger quantities, but 3D printing can be quicker for one-off parts or small runs. 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making complex net shapes. It .

The benefits of 3D printing over CNC Machining include creating parts with more complex geometries, rapid prototyping, and reduced waste. Also, 3D printing allows for better customization without retooling and offers the operator some level of design freedom and a chance to experiment and be more innovative with the design. Pros and cons: CNC is faster, more accurate, and can work with harder materials, but 3D printing is cheaper, easier, and can create more complex parts with less waste. Industry applications: Both CNC and 3D printing are used for prototyping and production in various industries, such as aerospace, military, and robotics. The decision between CNC machining and 3D printing ultimately depends on your project requirements, timeline, and budget. Here’s a quick breakdown to guide you: For High Precision and Strength: If you need parts that will handle heavy use, high temperatures, or stress, CNC machining is often the better choice.

Depending on your part requirements, budget, and timeline, CNC machining or 3D printing is the best choice. Here are some factors to consider: choose CNC machining for medium to high quantities of parts with simpler geometries.3D printing and CNC machining are among the most widely used rapid prototyping (RP) technologies today. Both methods enable quick production of prototypes, are suitable for creating metal and plastic components, and deliver highly accurate results.

real steel boxing champions hack mod apk download

Box junctions. These have criss-cross yellow lines painted on the road (see ‘Road markings‘). You MUST NOT enter the box until your exit road or lane is clear. However, you may enter the box and wait when you want to turn right, and are only stopped from doing so by oncoming traffic, or by other vehicles waiting to turn right.

3d printing is hype compared to cnc parts|3d printing and cnc machining